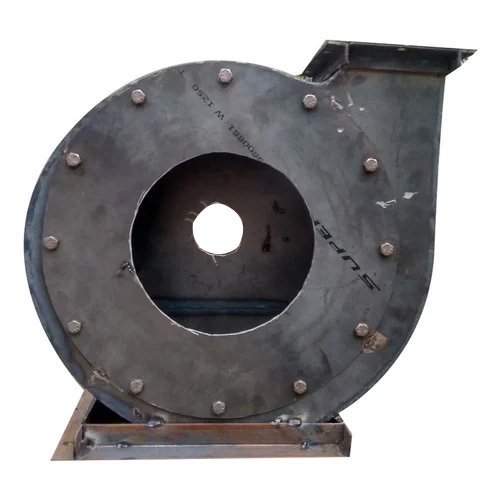

Boiler Centrifugal Fans

Product Details:

- Installation Type Floor

- Power Source Electrical

- Material Stainless Steel

- Click to View more

Boiler Centrifugal Fans Price And Quantity

- 10 Unit

- 50000 INR/Unit

Boiler Centrifugal Fans Product Specifications

- Stainless Steel

- Floor

- Electrical

Boiler Centrifugal Fans Trade Information

- Cash Advance (CA)

- 100 Unit Per Month

- 10 Days

- All India

Product Description

Industrial boiler systems use specialised fans called boiler centrifugal fans, commonly referred to as boiler fans or boiler blowers. They are made to deliver the essential air or gas flow for combustion, heat transfer, and effective boiler operation.

Boiler centrifugal fans are essential components of the boiler system because they provide a steady and controlled flow of gas or air to aid in combustion. They aid in establishing and preserving the ideal air-to-fuel ratio, which ensures effective fuel combustion and heat production.

On the air or flue gas side of the boiler system, the fans are normally installed. They take in ambient air or flue gas and send it to the burner or combustion chamber, giving the fuel for combustion the oxygen it needs. Boiler fans can occasionally be employed for additional tasks, such as supplying forced draught or induced draught air for better combustion and flue gas exhaust.

Centrifugal fans for boilers are made to withstand high temperatures, corrosive gases, and heavy particulate matter that could be present during combustion or flue gas emissions. They are built with durable materials that can handle these challenging conditions, and they come with features like insulation, erosion-resistant blades, and suitable sealing arrangements.

Boiler capacity, operating circumstances, fuel type, and particular requirements of the boiler system are only a few examples of the variables that influence the design and selection of centrifugal fans for boilers. For optimum performance, energy economy, and adherence to pollution laws, proper fan sizing and matching with the boiler's combustion characteristics are essential.

In conclusion, centrifugal boiler fans are crucial parts of industrial boiler systems. They provide efficient and dependable operation while maintaining safety and environmental compliance by supplying the required air or gas flow for burning.

FAQ

1. What is a centrifugal fan for a boiler?

Ans - A boiler centrifugal fan is a mechanical tool used in boiler systems for air filtration and ventilation. A duct may be used to draw air, steam, or gas using this particular style of fan.

2. What advantages can centrifugal fans offer?

Ans - The advantages of centrifugal fans include high pressure, quiet operation, greater efficiency, and little vibration. They are perfect for boiler systems with limited space because they are lightweight and small.

3. Under what conditions should centrifugal boiler fans be operated?

Ans - Extreme temperatures, high humidity, high temperatures, and corrosive situations can all be operated with centrifugal fans.

4. How should I go about choosing the right fan size for my boiler system?

Ans - To guarantee that it can handle the air flow required to maintain the boiler's top efficiency, the size of a centrifugal boiler fan should be chosen based on the size of the boiler. To improve the air flow, it should also be taken into account how many blades are on the fan.

5. What centrifugal boiler fan maintenance is necessary?

Ans - To keep a centrifugal boiler fan operating effectively and securely, regular maintenance is required. This entails regular inspection to look for any damage or corrosion and making sure the motor is oiled appropriately. To avoid any unforeseen malfunctions, belts and bearings should also be frequently replaced.