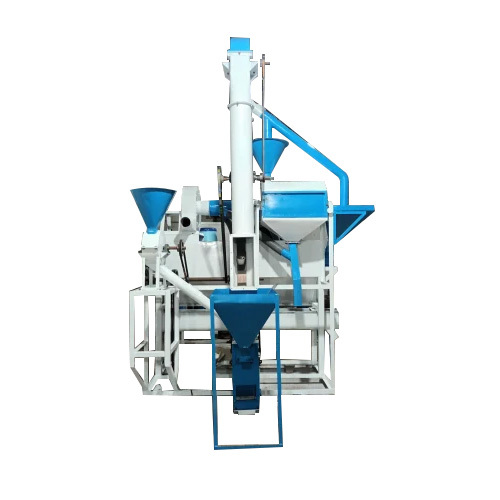

Dust Collector Dal Mill Machine

Product Details:

- General Use Industrial

- Material Stainless Steel

- Automatic Yes

- Feature High Efficiency

- Click to View more

Dust Collector Dal Mill Machine Price And Quantity

- 150000 INR/Unit

- 10 Unit

Dust Collector Dal Mill Machine Product Specifications

- Industrial

- High Efficiency

- Yes

- Stainless Steel

Dust Collector Dal Mill Machine Trade Information

- Cash Advance (CA)

- 100 Unit Per Month

- 10 Days

- All India

Product Description

A dust collecting system is included into a dust collector dal mill machine, a specialised type of dal mill machine that is designed to capture and remove dust produced during the dal milling process. By stopping dust from spreading into the air, it is intended to provide a clean and healthful working environment.

A dal mill machine's dust collection system frequently consists of an intake hood, ducting, filters, and a fan or blower. The milling motion that occurs as the pulses are processed through the machine may produce dust, which is collected by the intake cowl and sent through the ducting system.

Clean air is evacuated by the fan or blower as the dust-filled air goes through the filters, where the dust particles are separated and collected. The gathered dust can be recycled or disposed of as necessary.

The dal mill machine reduces the possibility of dust-related health risks for operators and provides a cleaner working environment by including a dust collector system. Additionally, it aids in preventing dust particles from contaminating dal products, guaranteeing superior quality and hygienic standards.

Depending on the size and configuration of the dal mill machine, the specific design and capacity of the dust collector system may change. It is crucial to choose a dust collector system that complies with all applicable safety and environmental laws and is appropriate for the specific dust load produced during the dal milling process.

FAQ

1. What exactly is a dal mill dust collector machine?

Ans - Pulses, especially split pulses, are ground into dal or flour using machinery known as a dust collector dal mill. To exclude dust and other impurities from the pulse ranges, it combines air aspiration and separation methods.

2. What advantages do dust collector dal mill machines offer?

Ans - Efficiency is the main advantage of employing a dust catcher dal mill machine. The technologies for air aspiration and separation use less energy than conventional techniques for turning pulses into dal or flour. By eliminating any lingering dust or other pollutants from the pulses, the finished product is also purer and cleaner.

3. Which kinds of pulses can be handled by a dust catcher dal mill machine?

Ans - A dust collector dal mill machine can efficiently process most varieties of pulses, including chickpeas, mung beans, kidney beans, peas, and fava beans.

4. How much room does a dust collector dal mill machine need?

Ans - Depending on the machine's capacity, the dust collector dal mill machine's size might range from a few square feet to hundreds of square feet.

5. How often must a dust collector dal mill machine be maintained?

Ans - To guarantee optimum efficiency, dust collector dal mill machines should undergo routine maintenance. This entails cleaning the device once a week and inspecting it for damage. Additionally, any parts that exhibit signs of deterioration have to be replaced as soon as feasible. To prevent respiratory problems for the operators, it's also critical to make sure the dust collector dal mill machine is dust-proofed.